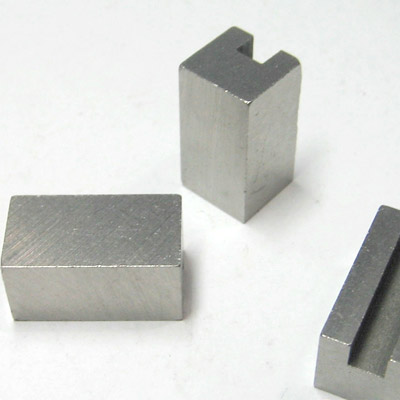

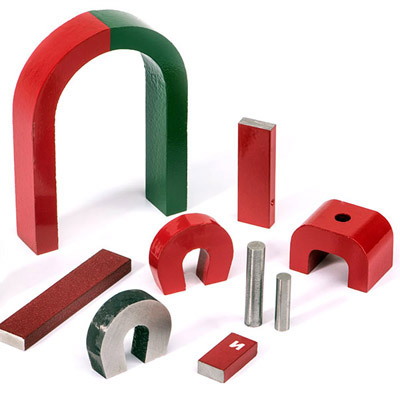

Cast AlNiCo magnet

Using patterns and simple moulding techniques, Cast AlNICo Magnet can be cast to form a vast range of complex shapes and sizes at an economical cost.

General Introduction of Cast AlNiCo Magnet

Using patterns and simple moulding techniques, Cast AlNICo Magnet can be cast to form a vast range of complex shapes and sizes at an economical cost.

Eclipse Magnetics Alnico magnets are ideal for high temperature applications up to 550ºC

Cast AlNICo Magnet is very stable, has good corrosion resistance and a typical hardness of 50 Rockwell C. Once cast, the material is so hard that the only machining possible is grinding

Cast AlNICo Magnet represents the most versatile magnet material available. The range of properties can be accurately designed for specific applications by changes to element analysis and heat treatment.

Typical Applications of Cast AlNICo Magnet

* ABS braking system magnets

* Reed switch operating magnets

* Electricity meter damping magnets

* Holding/clamping applications

* Microwave applications

* Weighing scale damping magnets

* Electropermanent systems

* Calibration magnets

* Heat treatment jigs and fixtures

What shapes can it be formed with Cast AlNICo Magnet?

|  |

|  |

|  |

|  |

Magnetic properties of Cast AlNiCo magnet:

| Equivalent MMPA Class | Grade | Remanence | Coercive Force | Max. energy product | Density | Rev. Temp. Coef. | Curie Temp. | Max. operating Temp. | ||||

| Br | Hc | (BH)max | D | Br | Hc | Tc | Tw | |||||

| mT | KGs | KA/M | Oe | KJ/m3 | MGOe | g/cm3 | %/°C | %/°C | °C | °C | ||

| ALNICO 3 | LN9 | 680 | 6.8 | 30 | 380 | 9.0 | 1.13 | 6.9 | -0.03 | -0.02 | 810 | 450 |

| ALNICO 2 | LNG12 | 720 | 7.2 | 45 | 500 | 12.4 | 1.55 | 7.0 | -0.03 | -0.02 | 810 | 450 |

| LNG13 | 700 | 7.0 | 48 | 600 | 12.8 | 1.60 | 7.0 | -0.03 | -0.02 | 810 | 450 | |

| ALNICO 5 | LNG37 | 1200 | 12.0 | 48 | 600 | 37.0 | 4.65 | 7.3 | -0.03 | -0.02 | 810 | 525 |

| LNG40 | 1250 | 12.5 | 48 | 600 | 40.0 | 5.00 | 7.3 | -0.02 | +0.02 | 860 | 525 | |

| LNG44 | 1250 | 12.5 | 52 | 650 | 44.0 | 5.50 | 7.3 | -0.02 | +0.02 | 860 | 525 | |

| ALNICO 5DG | LNG52 | 1300 | 13.0 | 56 | 700 | 52.0 | 6.50 | 7.3 | -0.02 | +0.02 | 860 | 525 |

| ALNICO 5-7 | LNG60 | 1350 | 13.5 | 59 | 740 | 60.0 | 7.50 | 7.3 | -0.02 | +0.02 | 860 | 525 |

| ALNICO 6 | LNGT28 | 1000 | 10.0 | 58 | 720 | 28.0 | 3.50 | 7.3 | -0.02 | +0.03 | 860 | 525 |

| ALNICO 8HC | LNGT36J | 700 | 7.0 | 140 | 1750 | 36.0 | 4.50 | 7.3 | -0.025 | +0.02 | 860 | 550 |

| ALNICO 8 | LNGT18 | 580 | 5.8 | 100 | 1250 | 18.0 | 2.20 | 7.3 | -0.025 | +0.02 | 860 | 550 |

| ALNICO 8 | LNGT32 | 800 | 8.0 | 100 | 1250 | 32.0 | 4.00 | 7.3 | -0.025 | +0.02 | 860 | 550 |

| LNGT40 | 800 | 8.0 | 110 | 1380 | 40.0 | 5.00 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| ALNICO 9 | LNGT60 | 900 | 9.0 | 110 | 1380 | 60.0 | 7.50 | 7.3 | -0.025 | +0.02 | 860 | 550 |

| LNGT72 | 1050 | 10.5 | 112 | 1400 | 72.0 | 9.00 | 7.3 | -0.025 | +0.02 | 860 | 550 | |