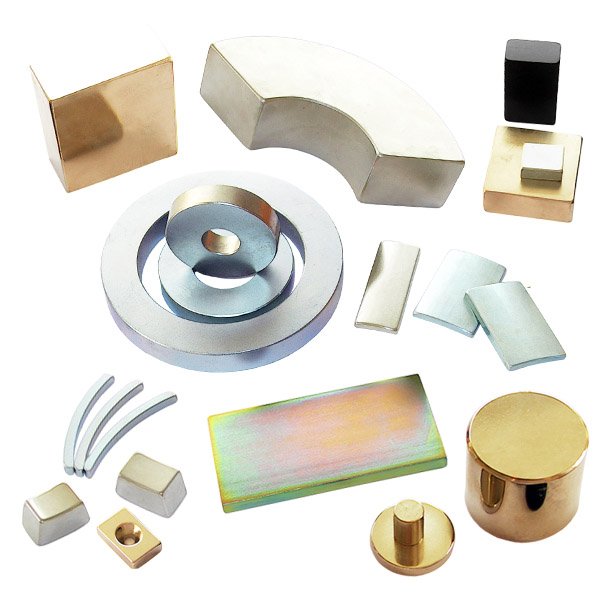

Dailymag Magnetics manufacture and export Various NdFeB magnets for industry use and daily use.We supply the different shape NdFeB magnets,like disc,cylinder,ring,block,arc and more neodymium magnets

Sintered NdFeB magnets (also known as "neo" magnets) are among the most popular magnets in the market today. The magnets have been available commercially since November 1984. They boast of offering the highest energy product (of any material/magnets today) and are available in a wide variety of sizes, grades and shapes (discs, arcs, blocks, spheres, trapezoid etc.).

Initially, NdFeB magnets were primarily used for making VCM’s (voice coil motors) in hard disk drives. This application still accounts for approximately 55 percent of all total sales of Sintered NdFeB magnets today. The magnets have many other applications due to their reasonable cost and superior magnetic properties. NdFeB magnets are used in making many tools/equipment such as communication tools, computer devices, motors, sensors, speakers and medical treatment instruments just to mention a few tools/equipment.

Sintered NdFeB magnets are made using an intermetallic compound; Nd2Fe14B which is composed of 2 rare earth atoms, one boron atom and 14 iron atoms. Besides the main-phase Nd2Fe14B (in NdFeB materials), there are some small quantities of rare Nd-rich phase (earth-rich phase), boron-rich phase and others. The earth-rich phase pins domain walls to give sintered NdFeB magnets a high coercive force. NdFeB magnets available today commercially have numerous partial alloying Nd and Fe substitution combinations which results in a variety of properties. Moreover, the magnets majorities are anisotropic which simply means they are capable of being magnetized in the orientation direction. Neo magnets are 3rd generation rare earth magnets which are simply the most commercially advanced and powerful magnets in the market today.

Get To Know Everything About NdFeB (Neodymium) Magnets

Among all the permanent magnets we have discovered to date, NdFeB magnets are the most extensively used type. As the name suggests, it is an alloy mostly made of Nd that is neodymium, Fe for iron, and B for Boron. One molecule of this compound consists of 2 atoms of Nd, 14 atoms of Fe, and one atom of Boron to form a tetragonal crystalline structure. Because it is composed of rare-earth metals, we often call it a rare-earth magnet.

Even so, there are several other permanent magnets available in the market like SmCo (Samarium Cobalt), Alnico, Ferrite, and many more, NdFeB magnets lie in the top priority for industrialists, commercialists, and other consumers. That is because it has the largest magnetic properties as compared to other permanent magnets. The magnetic strength is much larger than the permanent magnets mentioned above. In addition to that, it is way cheaper and therefore it is a very good choice for technical applications. Neodymium magnets have a considerable contribution to the evolution of technology. Designing small mechanical parts as possible with neodymium magnets because it is very powerful even in a small volume. But having all these, there remains a risk of getting corroded. That is why these magnets need to be coated with compounds like NiCuNi, NiCuEpoxy, Zn, and Au.

Depending on the manufacturing process, NdFeB magnets are classified into two types. One is called “sintered NdFeB magnets” and the other type is called “bonded NdFeB magnets”. Due to their compact size, large magnetic coercivity, and remanence, sintered NdFeB magnets are extremely powerful products. On the other hand, bonded NdFeB magnets are much more flexible. They are used to create complex shapes with multiple poles. Along with that, they are much lighter, thus they are ideal for delicate machinery. Almost every kind of industry like automobile, aerospace, defense, white goods, lighting, motors, generators, and food factories all use neodymium magnets.

Features and Characteristics

Different Grades and Shapes of NdFeB magnets

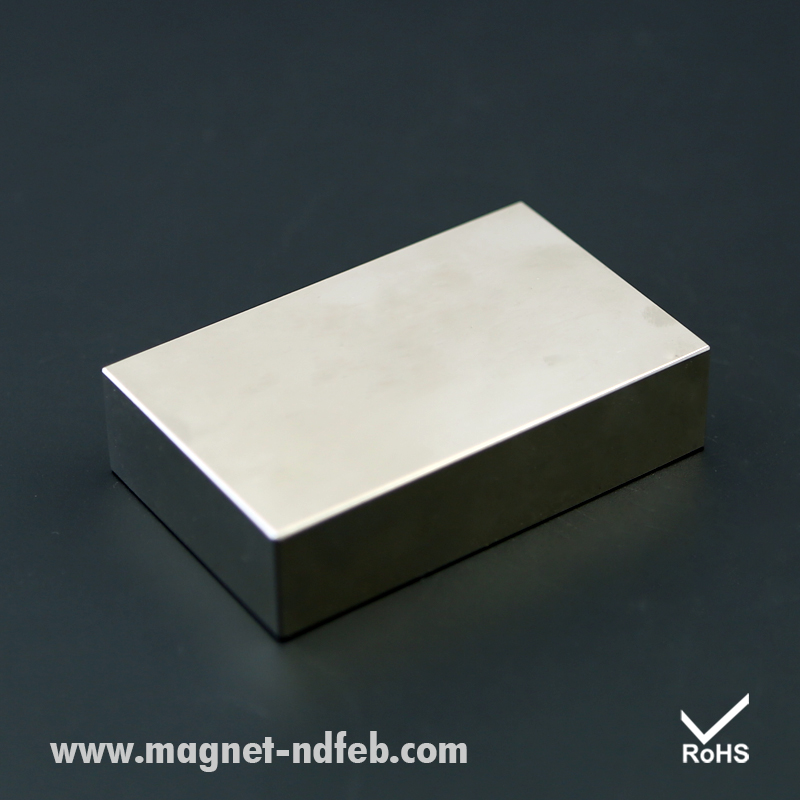

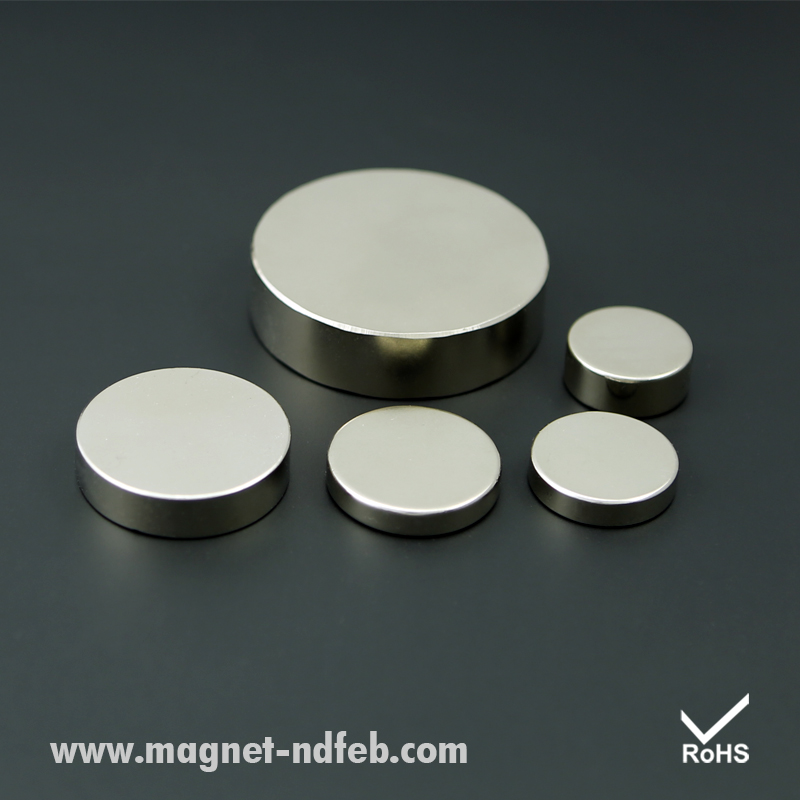

There are nearly 55 different NdFeB magnets classified by grades and shapes. For instance, N35, N38, N42, N38SH, and many more. Grade is the number written after N. Rating of each kind is given depending on the constituent material. To choose the type ideally suited for the consumer, they need to know the grading. The Greater the grade, the more is the magnetic strength. Currently, the top grade NdFeB magnet is N52. Magnet’s temperature rating is denoted by the letters written after the grading or number. If there are no letters specified, that means the maximum temperature the magnet can tolerate while working properly is 80 degrees Celsius. The shapes in which the NdFeB magnet is usually available are mainly blocks, rings, and arcs. Also, discs, spheres, trapezoids, triangle shapes are available. Since NdFeB magnets are quite flexible, especially the bonded versions, many other shapes can also be made on-demand.

The Perfect temperature for NdFeB magnets

We all know that with an increase in temperature, the magnetic strength dips and so does the overall performance. On the contrary, magnetic strength increases when the temperature falls. So magnetic components will give their best performance at very low temperatures. This phenomenon not only applies to neodymium but for each kind of magnets. Even at sufficiently low temperatures like -130 degrees Celsius, NdFeB magnets work pretty well. With some modification, it has been possible to make certain types of NdFeB magnets that can work decently even at very large temperatures. At temperatures beyond that particular limit, their properties start to change. That amount of heat is fairly potent to take away its magnetism, temporarily or maybe permanently.

With an increase of one degree Celsius the magnetic power of the NdFeB magnet decreases by 0.11%. This tiny loss can be compensated by cooling provided the limiting temperature is not crossed. However, if the limit is exceeded, no such loss can be recovered, howsoever small it be. Up to 80 degrees Celsius, the magnetic field output rises. But beyond that performance level starts dipping. The temperature rating is given according to the different levels up to which magnets can tolerate. Letters used to rate are M, H, SH, UH, EH, or AH. The tolerance power from up to 100 degrees Celsius to 230 degrees Celsius is rated in the above-given order. Not only extreme heat, even simultaneous hot-cold cycles can damage the performance. In general, it is advised to use these magnets in temperatures below 130 degrees Celsius.

Surface Treatment is necessary

Sintered NdFeB magnets corrode much faster and easier. This can even crumble the magnet into powder. Thus, it is necessary to give the magnet a surface coating otherwise it may rust in humid conditions. The most popular coating is Ni-Cu-Ni plating. There are nearly 40 types of coating among which NiCuEpoxy, Zn, and Au are mostly used besides NiCuNi.

Advantages and Disadvantages of NdFeB magnets

Advantages

1. It can give maximum performance even in the smallest of volumes. This makes it ideal for small components.

2. Performs decently in very cold conditions.

3. High Coercivity thus high resistance towards demagnetization.

Disadvantages

1. Gets easily corroded. Needs a coating to protect the iron from rusting.

2. NxxT and L-NxxT alloys are expensive and are also vulnerable to rusting.

3. Higher temperature versions are costly.

4. At conditions above 180 degrees Celsius, SmCo proves to be better.

Applications

Depending on the needs of consumers and industries, manufacturers create different shapes of NdFeB magnets. Bar, blocks, discs, pot, and ring-shaped magnets are widely used. Hooks and threaded magnets are also made. NdFeB magnets have replaced other kinds in many products. Modern machines where a strong permanent magnet is used, for instance, electric motors which are present in almost every machine around us, on hard disk drives inside computers, electronic cigarette firing switches, door locks, speakers, earphones and headphones. In larger scenarios, they are present in generators inside wind turbines, electric steering and stepper motors, and many more. They are also used in jewelry, toys, and even in sport parachutes. In the medical field, they are used in MRI- magnetic resonance imaging. They are planted near the gastroesophageal sphincter surgically to treat GERD.