Magnetic Push-Pull Attractor

Pull-and-push Magnetic Attractor (Magnetic Push-Pull attractor) Component Part: Stainless steel body non-responsive to magnets plus high quality and high performance materials.

Magnetic Push-Pull Attractor

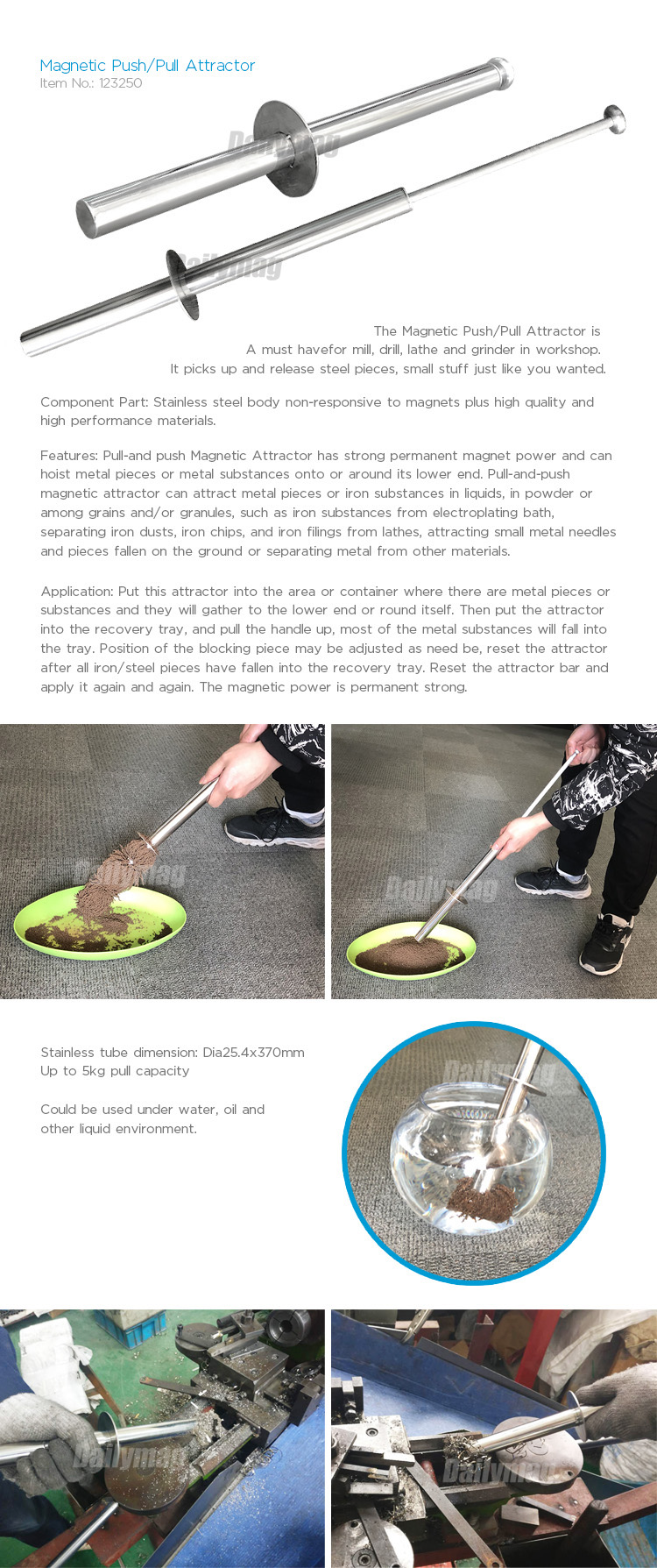

Item No.: 123250 Magnetic Push-Pull Attractor

Stainless tube dimension: Dia25.4x370mm

Up to 5kg pull capacity

Could be used under water, oil and other liquid environment.

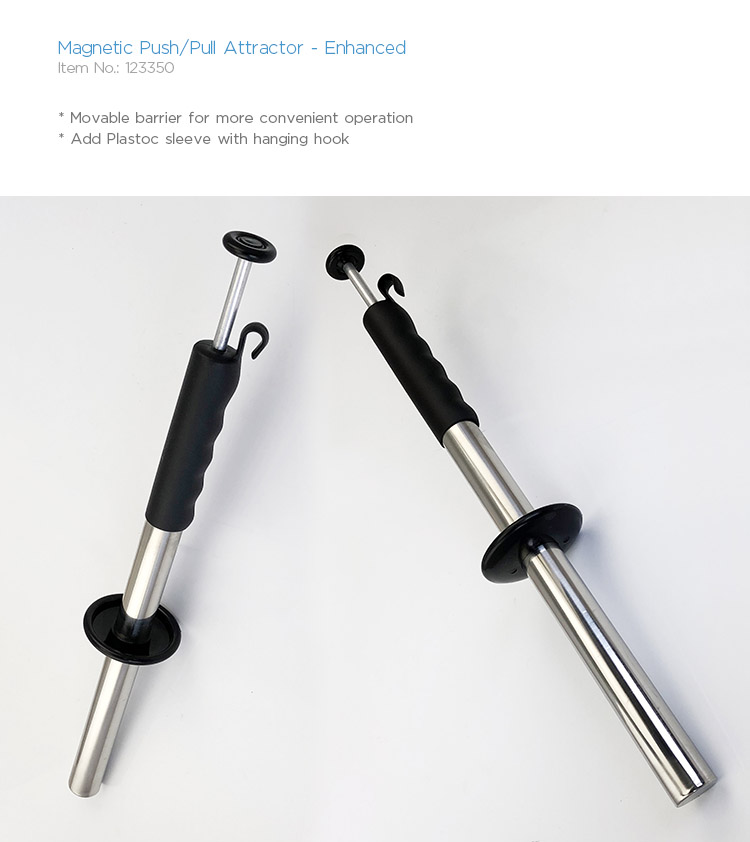

Item No.: 123350 Magnetic Push-Pull Attractor - Enhanced

* Movable barrier for more convenient operation

* Add Plastoc sleeve with hanging hook

What is Pull-and-push Magnetic Attractor (Magnetic Push-Pull attractor) ?

The Magnetic Push-Pull Attractor is A must havefor mill, drill, lathe and grinder in workshop. It picks up and release steel pieces, small stuff just like you wanted.

Component Part: Stainless steel body non-responsive to magnets plus high quality and high performance materials.

Features: Pull-and push Magnetic Attractor has strong permanent magnet power and can hoist metal pieces or metal substances onto or around its lower end. Pull-and-push magnetic attractor can attract metal pieces or iron substances in liquids, in powder or among grains and/or granules, such as iron substances from electroplating bath, separating iron dusts, iron chips, and iron filings from lathes, attracting small metal needles and pieces fallen on the ground or separating metal from other materials.

Application: Put this attractor into the area or container where there are metal pieces or substances and they will gather to the lower end or round itself. Then put the attractor into the recovery tray, and pull the handle up, most of the metal substances will fall into the tray. Position of the blocking piece may be adjusted as need be, reset the attractor after all iron/steel pieces have fallen into the recovery tray. Reset the attractor bar and apply it again and again. The magnetic power will never weaken.

Delivering products that are pure and free of all impurities establishes a company's trustworthiness and reputation. If you own a chemical firm or operate in the agricultural industry, or if you work in the pharmaceutical industry or work with plastic and chemical materials, this is exactly the type of service you need.

Companies have a product preparation process that includes storing raw materials, transportation, and storage. Also, grinding dry materials, particularly food products, via a carbon or stainless steel chute may result in ferrous contaminated materials that are unsafe to eat, and the product must be scraped clean of impurities in order to generate a profit; otherwise, it may be sold for less money.

That would be a disaster for any business.

So, what are your options?

Try our magnetic separator rods, which offer unique properties that make the workflow, go more smoothly.

They are made of permanent magnet:

Indestructible, everlasting – these are your thoughts about the magnetic rod and it’s correct for the characteristics it possesses, aside from the fact that this rod can be employed at high temperatures from a scientific standpoint. With high temperatures, every magnetic material loses its strength, affecting its capacity to attract ferrous materials, Permanent magnets, on the other hand, can perform at high temperatures but have an irreversible capacity to restore to their full attraction capability in the event of a power loss.

It’s compatible to use for dry, free-flowing materials in bulk quantity:

Materials can be classed as dry, moist, or liquid, with sizes ranging from fine powdered to large rocks flowing over the fast conveyor strips; do you believe the magnetic separator will be up to the task?

Fine metallic contamination may exist in the materials, which can be separated by restricting the flow vertically as the product cascades down the pipe. This magnetic tube attracts ferrous materials quickly and can be inserted in the bulk material stream for a simple split.

Is it cost-effective to install the magnetic rod?

Consider it from the buyer's point of view. Will you buy the product if it contains contaminants? Would you put your loved ones' lives in jeopardy, especially if it involves food? Would you want to buy from that label again if ferrous material is discovered in any of the products?

If all of the responses are no, it's time to move on to the sellers’ viewpoint.

It would be irrational to believe that raw materials that have been housed in large metallic tanks do not contain ferrous spruces, with shipping being the primary cause for outsourcing raw supplies.

It's time to check the gradients of your products, to provide a pure and healthy alternative, to screen for impurities within - which could be simple to purchase and cost-effective with these rods that are considered to remove micron sized contaminants with optimal solutions provided by our engineering experts for individual setup.

It's worth noting that the magnetic rod is simple to clean!

The rod's basic design with a push and pull mechanism makes collecting contaminated particles a simple operation that can be completed in seconds by pressing the rod, which releases the pollutants into any created plan, such as a collecting unit or a plate. When planning for procurement, using this method could be cost-effective, as just by pulling the rod handle causes the impure particles to fall spontaneously, making it a feasible technique to use on a daily basis without causing too much disruption.

Is Cleaning Ferrous Materials 100 % efficient with this separator rod?

When the rod is constructed of rare earth, it has an M6 thread inserted inside for easy installation, and it is supplied with a NdFeb permanent magnet, it is easy to mount in any position throughout the filtration process, and it has a high attraction capacity for fine coarse particles between the grains of sugars, or granules of wheat, further smooth powder, it can never go wrong..

Is this magnetic separator only useable if I own a factory?

Or could Shop vendors use it too?

Anyone who has some hardware items lying around can be using this rod to remove or exclude bolts, welding rods, nails and such. There are some everyday scenarios that everyone is aware of , there is no way to get out of it until a permanent solution is thought of, and that is what our people like to do providing solutions to daily life problems with the main tool of magnet, as the believe goes attraction never fails. Imagine using needles at home, and when you drop the bundle, the only thing to click is several hours of survey to find the fallen little sharp pieces of metal – that could be harmful and if not handled properly with care, can end you up wracked into a hospital. Scared of the vision? Let’s talk for the solution to it:

The great part of sorting metal pieces is the nature of attraction to magnets, which is a sure solution to picking up any spare parts in form of powder, thin scraps, filings or such. The beauty lies in the design of the product that is the Pull & Push Magnetic Attractor, made with a rod protruding from the magnet that is of stainless steel, anti-rusting material with a stick of magnetized rod, which becomes magnetic when pulled out with a push at the edge. When the pull ends the magnet returns to its own original state, lowering its magnetic capacity, safe within the circular cavity inside.

Even the chemical laboratories’ are no short of these magnetic rods, for picking up all the iron filings surfaced at the desks for easy scientific study processes.

Imagine finding a piece of rice in the straw if such rods had not been invented. Magnets are the head tech department pushing forward with each selected product, seeking to place solutions on the most basic levels, which would be cost effective and bearable for all, making the product leverage for customer satisfaction.