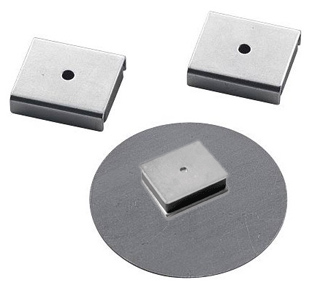

Channel Magnet, Latch Magnet

Channel Magnet are formed by a strong ceramic magnet and Zinc-Plated steel parts. Used mainly as a door latch, it can also be used to hold nameplates, fixtures or other ferrous metal objects. Channel magnets are highly resistant to heat.

Channel Magnet, Latch Magnet

Choose your suitable Channel Magnet

What is Channel Magnet?

Channel Magnet are formed by a strong ceramic magnet and Zinc-Plated steel parts. Ceramic Magnet is fixed in the steel pieces to create a channel magnet. We call them latch magnets, too. Channel magnet will create strong power on one large face. They provide up to more times the strength of individual magnet. Channel Magnet features a middle hole for mounting. Used mainly as a door latch, it can also be used to hold nameplates, fixtures or other ferrous metal objects. Channel magnets are highly resistant to heat.

Channel Magnets can be manufactured according to customers' specifications. All round bases and some channels and sandwiches shapes are available in a zinc coating, or black powder coat finish.

Latch Magnet >>

Neodymium Channel Magnets

General Motors and Sumitomo Special metals company were the first in the history to develop the neodymium magnets back in the year 1982. Neodymium channel magnets are basically built from a Super strong neodymium magnet. The neodymium magnet is kept in a case inside a steel channel circuit which is coated by the chrome or nickel. In this way, the holding force of the neodymium magnets is increased by up to 40 kilograms approximately. Keeping the neodymium magnets inside the steel case also protects the magnets from any kind of damages while using them in our daily lives.

Neodymium channel magnets are seen to have more magnetic performance in comparison to the standard bar magnets or even standard neodymium magnets. This is due to the reason that the steel circuit accumulates or concentrates the entire magnetic field of the magnet to the one side, or the surface of these magnets. These magnets are encased with a triple layer consisting of Nickel , copper and cobalt metals. The layering is done with the help of an electrolytic process which provides protection to the magnet from external damages such as corrosion, oxidation or any other physical loss.

Practical applications of neodymium channel magnets

Neodymium magnets have a number of practical applications in our daily life. We can use them to store all the nuts and bolts at the same place, they can be also used to keep all of our tools at the same place to keep them organized etc. Apart from these, neodymium channel magnets are also used for many practical applications like mounting things on one another, holding things together, fixing things etc which generally require a higher holding force. Generally it is seen that the Neodymium channel magnets having two Countersink holes at the ends of a magnet is having more holding power than a neodymium channel magnet having only one countersink hole of the same size.

The two countersinks holes at the ends of a neodymium channel magnet which allow the flush installation through them and due to this the holding power of these magnets is maximized in them. These can also be used in applications like installations of various lights, windows displays etc. These magnets come with the countersink holes which will allow them to fit screws and nuts bolts in them. Neodymium channel magnets are also used in the manufacturing of the hard disk drives used in computers. These magnets are also widely used in electronic equipments like Sound mic, Headphones , loudspeakers etc. Electric motors use neodymium magnets to convert the electrical energy into mechanical energy whereas the electric generator uses the same magnet to convert mechanical energy into the electrical energy. Other than that, neodymium magnets are also used in medical applications like MRI scans, magnetic medical therapies etc.

Hazards involved with neodymium magnets

Neodymium magnets are very strong magnets in nature. If two neodymium magnets are brought very close to each other, then they will get attracted to each other very rapidly which will cause them to slam with each other and they may even break. This is also a very common cause of breaking of the neodymium magnets.

If such incident happened during the operations involving neodymium magnets, then the magnets may be chipped and the chips may be fly at high speed and harm someone badly. The chips flying at high speed may cause injury or damage to any person’s sensitive organs such as eyes. Therefore, it is recommended to take precautions during the handling or operation of these magnets. Neodymium magnets can also adversely affect the pace makers installed in the heart patients which can lead to severe health issues for them. It is also advisable to keep the neodymium magnets from out of the reach of the children as they may mishandle the magnet and cause any harm to them.