Holding Magnets (Holding And Retrieving Magnet)

We supply a wide range of Holding and Retrieving Magnets, including Standards Holding and Retrieving Magnets, Super Holding and Retrieving Magnets and Common Holding and Retrieving Magnets to worldwide customers. You can customized your own size Holding and Retrieving Magnets, too.

Holding Magnets (Holding And Retrieving Magnet)

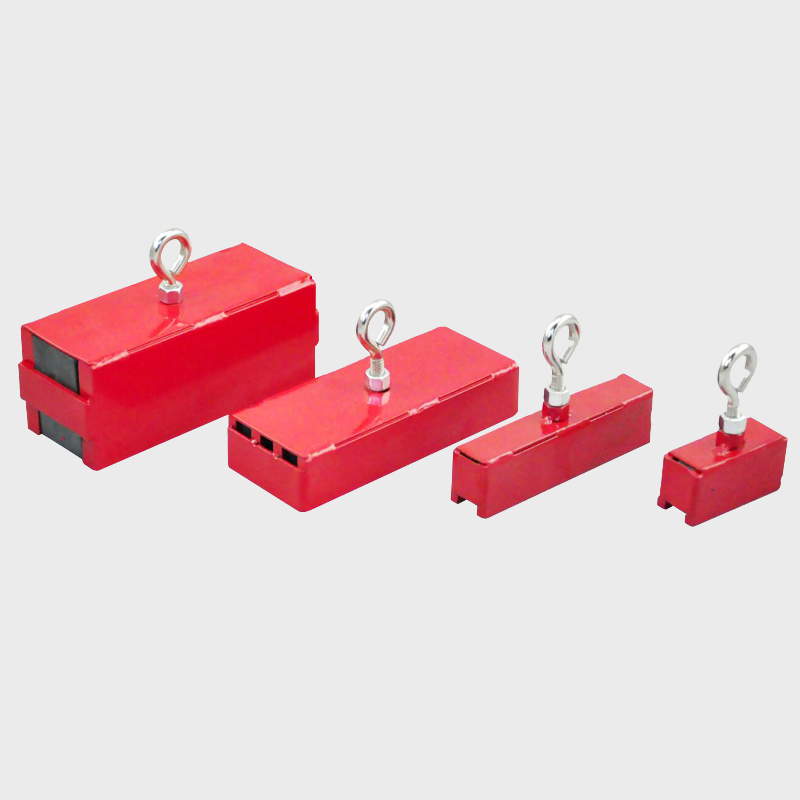

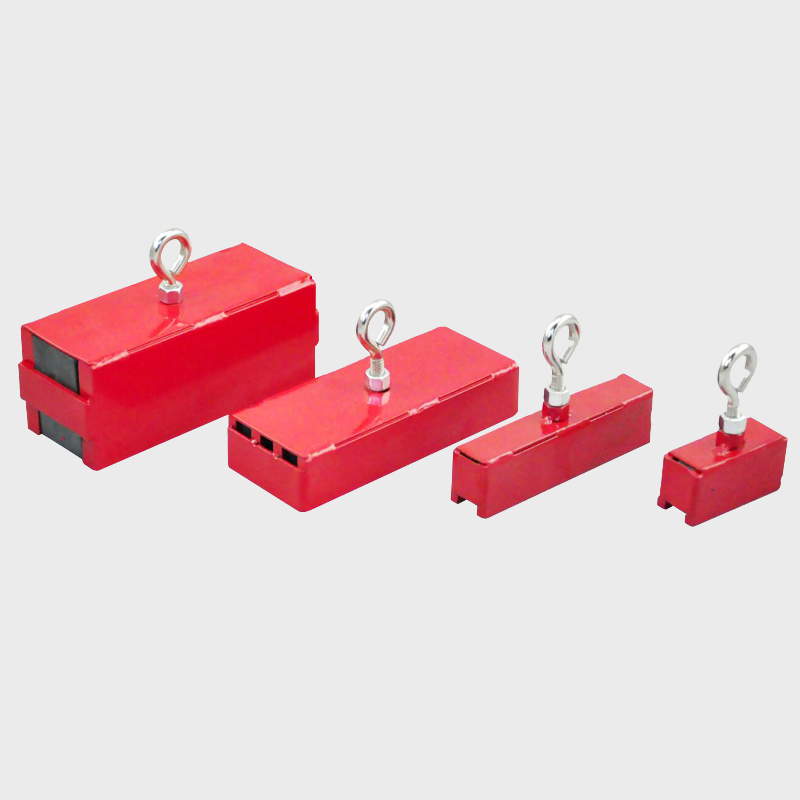

Choose your suitable Holding Magnet

Holding and Retrieving Magnets, Handle Magnets

| Item No. | Description |

| 231025 | Standard Holding and Retrieving Magnet, Lifts up to 25LBS |

| 231050 | Standard Holding and Retrieving Magnet, Lifts up to 50LBS |

| 231100 | Standard Holding and Retrieving Magnet, Lifts up to 75LBS |

| 231150 | Standard Holding and Retrieving Magnet, Lifts up to 150LBS |

| 231225 | Standard Holding and Retrieving Magnet, Lifts up to 225LBS |

| 232040 | Super Holding and Retrieving Magnet, Lifts up to 40LBS |

| 233040 | Common Holding and Retrieving Magnet, Lifts up to 40LBS |

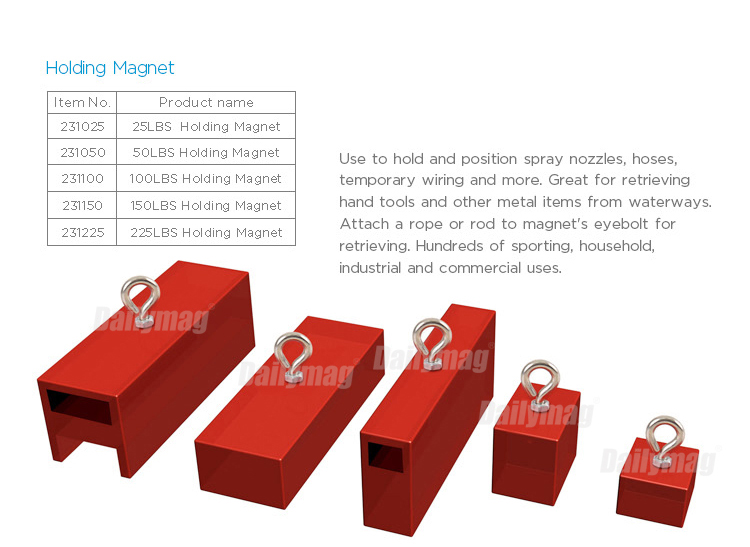

Holding and Retrieving Magnets (Holding Magnet)

We supply a wide range of Holding and Retrieving Magnets, including Standards Holding and Retrieving Magnets, Super Holding and Retrieving Magnets and Common Holding and Retrieving Magnets to worldwide customers. You can customized your own size Holding and Retrieving Magnets, too.

Standard and Common Holding and Retrieving Magnets can be plated with both Red painting and Black painting. A hole is built-in the magnets to attach the eyebolt for different application. Eyebolt and nut are included in each magnet. Holding and Retrieving magnets offer hundreds of commercial and industrial uses, including retrieving hand tools and other metal items from waterways, retrieving an outboard motor from the bottom of a lake, and sporting, household, industrial and commercial uses. Eyebolt and nuts included. They have high water resistance and heat resistance performance. They contain good quality of ceramic (ferrite) magnets and is capable of lifting up to 25LBS - 225LBS. Under normal use, permanent magnetism guaranteed.

Super Holding and Retrieving Magnets are special design with Heavy-duty retrieving function. They are made of plastic and magnets. With this design, they have good appearance and prevent potential injuring during working time. Please add the enclosed eyebolt on the top or side of the Holding Magnet and use to hold, lift and hang objects. Hundreds of uses are possible. NOTE: They are not fit for working in the water or heating environment.

NOTE: Pounds pull is rated by vertical test on 3/8in. thick ground steel plate. Pounds pull rating will be reduced if the item you wish to lift is thinner, painted, or an uneven surface.

You have been living in this era, surrounded all by electromagnetic fields, ever wonder where would you find it? On your fridge doors, the small discs inside your speakers, behind the door locks, all in all – MAGNETS have always aided HUMANS for holding all together, this is how the technology has poured in to a new way of using magnets, we know today as Holding Magnets or Pot Magnets, as the name suggest the magnet assemblies are placed inside the ferromagnetic body, while having the active magnet kept faced towards the opening, so that the magnetic field is concentrated, Why?

To better support the flaps, doors, shelves conjoining the surfaces without failing into a split.

There are some benefits of using the holding magnets that would make you opt for it without frenzy.

1-The proper combination of metals kept outside as coating, keeps the magnet safe from cracking or doesn’t break due to the pressure exerted on it, that’s why it is a sure choice when required for heavy duty works.

2-The design makes it an easy to install product, without any haphazard situations to follow or any chaos to cuddle.

3-As the technological sector raises its benchmark, the surfaces used in the industrial or educational systems for offices are made of Steel, which is why using these holding magnets with preserve a strong grip onto anything, supported with the proper shape and size of these magnets.

It’s obvious that everyone requires holding magnets according to their work space requirements, which is why let us know the designs available to us, for the choice of best options for deliverable binding.

First Type of Holding Magnet:

The one which comes with a hole, the donut type holding magnets, is designed to be used with screws. Due to the flat surface and complete binding force, these magnets result as the most powerful holding magnets, and that is why they are so much in demand.

Second Type is with Complete Hole:

The little difference it has that it comes with the edges which are made circular, leaving the choice open for the user to either strap it or close it with a nut.

Third Type is Screw Design:

With a simple T hanging out from the main disc, this magnet has an additional impact, when required to be posted inside some thin areas for a professional outlook, where the magnets are not visible, with the steel finesse. The latches on the doors would be quite feasibly glued with these magnets to make them adhere to the walls, for a beautiful opening, without door wavering with an abrupt thwart.

Fourth is Hanging Hook Style:

The magnetic base is flat with the other side protruding in the shape of a hook. This design is a genius formation for any setup that is made through wires or are meeting at different altitudes, which makes this hanging hook magnetic assemble easy to hold and hang and required materials for a suitable energy level. The best part is that the round shapes can also be crafted according to the user’s need and the capability of the holding magnet required.

Before you jump into buying it, be wary of the technical details:

You would find magnets within a diameter range of 20 to 100mm, with differing holding powers, varying with the sizes between 80 to 3700 Newton. The holding power mechanisms should be considered with proper understating as the magnetic fields are activated when it has no air fields between within the work surfaces.

Disclaimer: If the holding magnet’s face is irritated due to staining or unevenness, it can lower the holding power of the magnets, resulting in the damage or uselessness of the work space. That’s why installing; although easier, should be done with utter care and balance.

Some points to NOTE, for information purposes:

There is a difference between holding magnets and permanent holding magnets. To understand it, you would recall the science classes you had in elementary levels. Holding Magnets are fitted in with coils that are energized to create a magnetic field, where as the permanent holding magnet doesn’t need to break their power of holding or attraction off, that is it contains a permanent magnet along with the coil and serves a higher functionality.

If you are wondering how to do a quality check for the strength of the holding magnet, these points might help you:

Keep in mind these four things, when you are looking to buy for holding magnets:

1- They work best when are electro galvanized, to protect the surface from corrosion.

2- A simple layer of grease and dust or nickel plating on the holding magnet can affect the distance between the two surfaces, making an air gap, which could prove hazardous as a result, as it strongly affects the work efficiency power of the magnet.

3-Keep in mind: The thickness of the work place which is supposed to be held by holding magnets. The focus path is the thicker the part to be held, the better the achievement of the adherence due to the greater number of magnetic fields available crossing through the path. When the work space becomes thin, it’s a bit riskier and harder to launch more numbers of magnetic field lines in the area, making the force insufficient for the grasp.

4- The holding magnets are mentioned with the force they can exert on the sticking materials, but it should be pondered upon that any surface that has been heated up, made of iron would have a low magnetic permeability, whilst any steel with low carbon would have high tendency for magnetic permeability.

5-The ferrous magnetic part is the main formulator for the energy magnetic fields. If for any reasons, the ferrous magnet doesn’t cover both the sides of the poles, which could be due to the roughness of the space, holes have been drilled in, making the surface out of contact, or the magnet is not centered properly, the force follows a reduction path, lowering the impact of the holding magnets.

Hope you have complete information for the product. It could be used with versatility in nooks and crooks to help you save the day with positive solution thinking skills.