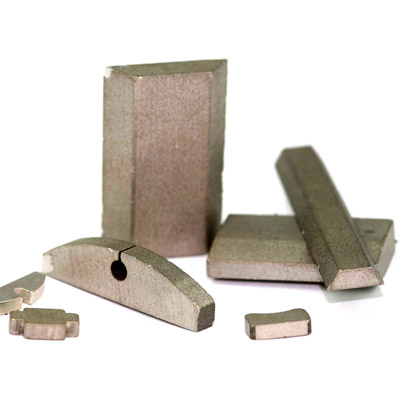

What shapes can it be formed with Sintered SmCo magnet? Sintered SmCo Magnet

|

|

|

|

Magnetic properties of SmCo5 (Sintered SmCo Magnet)

| Material | Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max.

energy product |

Curie Temperature |

Max. Operating Temperature |

Temperature Coefficient of Br |

Temperature Coefficient of Hc |

||||

| Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||||||

| SmCo5 (Smpr)co5 |

T | KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGoe | °C | °C | %°C | %°C | |

| YX- 16 |

0.81-0.85 | 8.1- 8.5 |

620-660 | 7.8- 8.3 |

1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.05 | -0.3 | |

| YX- 18 |

0.85-0.9 | 8.5- 9.0 |

660-700 | 8.3- 8.8 |

1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.05 | -0.3 | |

| YX- 20 |

0.9-0.94 | 9.0- 9.4 |

680-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.05 | -0.3 | |

| YX- 22 |

0.92-0.96 | 9.2- 9.6 |

710-750 | 8.9-9.4 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.05 | -0.3 | |

| YX- 24 |

0.96-1.0 | 9.6- 10.0 |

730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.05 | -0.3 | |

| SmCo5 | YX- 20s |

0.9-0.94 | 9.0- 9.4 |

680-725 | 8.5-9.1 | 1433-1830 | 18-23 | 143-160 | 18-20 | 750 | 250 | -0.05 | -0.3 |

| YX- 22s |

0.92-0.96 | 9.2- 9.6 |

710-750 | 8.9-9.4 | 1433-1830 | 18-23 | 160-175 | 20-22 | 750 | 250 | -0.05 | -0.3 | |

| Low temperature coefficient SmCo5 (SmGd)Co5 |

LTc (YX- 10) |

0.59-0.63 | 5.9- 6.3 |

460-493 | 5.8-6.2 | 1430-1830 | 18-23 | 68-80 | 8.5-10 | 700 | 250 | Temperature | Temperature Coefficient of Br %°C |

| 20-100°C | -0.004 | ||||||||||||

| 100-200°C | -0.021 | ||||||||||||

| 200-300°C | -0.042 | ||||||||||||

| ce(coFecu)5 | YX- 12 |

0.70-0.74 | 7.0- 7.4 |

358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

Magnetic properties of Sm2Co17 (Sintered SmCo Magnet)

| Material | Grade | Remanence | Coercive Force | Intrinsic Coercive Force | Max.

energy product |

Curie Temperature |

Max. Operating Temperature |

Temperature Coefficient of Br |

Temperature Coefficient of Hc |

||||

| Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||||||

| Sm2Co17 Sm2 (CoFecuzr)17 |

YXG- 24H |

0.95-1.02 | 9.5- 10.2 |

700-750 | 8.7-9.4 | =1990 | =25 | 175-191 | 22-24 | 800 | 350 | -0.03 | -0.2 |

| YXG- 26H |

1.02-1.05 | 10.2- 10.5 |

750-780 | 9.4-9.8 | =1990 | =25 | 191-207 | 24-26 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 28H |

1.03-1.08 | 10.3- 10.8 |

756-796 | 9.5-10 | =1990 | =25 | 207-220 | 26-28 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 30H |

1.08-1.10 | 10.8- 11.0 |

788-835 | 9.9-10.5 | =1990 | =25 | 220-240 | 28-30 | 800 | 350 | -0.03 | -0.2 | |

| YXG- 24 |

0.95-1.02 | 9.5- 10.2 |

700-750 | 8.7-9.4 | =1433 | =18 | 175-191 | 22-24 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 26 |

1.02-1.05 | 10.2- 10.5 |

750-780 | 9.4-9.8 | =1433 | =18 | 191-207 | 24-26 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28 |

1.03-1.08 | 10.3- 10.8 |

756-796 | 9.5-10 | =1433 | =18 | 207-220 | 26-28 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 30 |

1.08-1.10 | 10.8- 11.0 |

788-835 | 9.9-10.5 | =1433 | =18 | 220-240 | 28-30 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 26M |

1.02-1.05 | 10.2- 10.5 |

750-780 | 9.4-9.8 | 955-1273 | 12-16 | 191-207 | 24-26 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28M |

1.03-1.08 | 10.3- 10.8 |

756-796 | 9.5-10.0 | 955-1273 | 12-16 | 207-220 | 26-28 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 30M |

1.08-1.10 | 10.8- 11.0 |

788-835 | 9.9-10.5 | 955-1273 | 12-16 | 220-240 | 28-30 | 800 | 300 | -0.03 | -0.2 | |

| YXG- 28L |

1.02-1.08 | 10.2- 10.8 |

398-445 | 5.0-5.6 | 400-520 | 5.2-6.5 | 207-220 | 26-28 | 800 | 250 | -0.03 | -0.2 | |

| YXG- 30L |

1.08-1.15 | 10.8- 11.5 |

398-445 | 5.0-5.6 | 400-520 | 5.2-6.5 | 220-240 | 28-30 | 800 | 250 | -0.03 | -0.2 | |

| Low temperature coefficient Sm2Co17 (SmEr)2 (CoTM)17 |

LTC (YXG- 22) |

0.94-0.98 | 9.4- 9.8 |

668-715 | 8.4-9.0 | 1194-1591 | 15-20 | 167-183 | 21-23 | 840 | 300 | Temperature | Temperature Coefficient of Br %°C |

| -50-25°C | +0.005 | ||||||||||||

| 20-100°C | +0.012 | ||||||||||||

| 100-200°C | +0.006 | ||||||||||||

| 200-300°C | -0.025 | ||||||||||||

Characteristic comparisons of permanent magnetic materials:

|

Materials |

(BH)max |

Hcj |

Br Tc |

(Working temperature)max |

Anti-causticity |

|

SmCo1:5 |

16-25 |

15-25 |

-0.05 |

200-250 |

Good |

|

SmCo2:17 |

22-30 |

6-30 |

-0.03 |

300-350 |

Good |

|

NdFeB |

26-52 |

12-30 |

-0.11 |

80-200 |

Bad |

|

Ferrite magnet |

3-4.5 |

3-4.5 |

-0.19 |

200-300 |

Good |

|

AINiCo |

5-10 |

1-1.8 |

-0.03 |

450-500 |

Excellent |

Process Flow:

Raw material-----Mixing-----Melting-----Power-----Pressing-----Sintering----Magnetic Inspection-----Cutting and Grinding-----Inspection-----Packing and Shipping

Sintered SmCo Magnet, SmCo Permanent Magnet, Magnetic Material for you now