Pot Magnets, Mounting Magnets

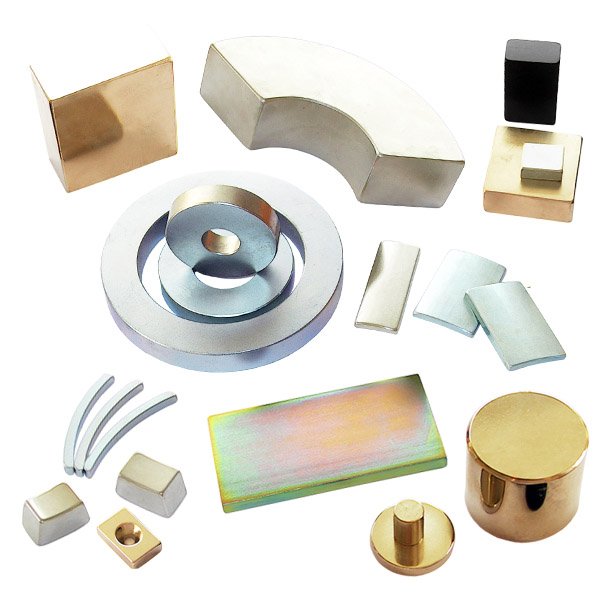

Pot magnets (Mounting Magnets) are made up of magnets (NdFeB, SmCo, AlNiCo or Hard Ferrite) and other spare parts, such as metal, plastic, rubber and other components. Sometimes Pot magnets can meet some special requirements while a single magnet can not do. In the meantime, using pot magnets can save more cost than just using magnets and gain the same purpose.

POT MAGNETS, MOUNTING MAGNETS

Choose your suitable Mounting Magnets, Pot Magnets

Choose your suitable Mounting Magnets, Pot Magnets

|  |

| Eye Screw Pot Magnet(Mounting Magnet) | Pot Magnet Assembly(Magnetic Assemblies ) |

|  |

| Cast AlNiCo magnet | Rubber Coated Pot Magnet |

|  |

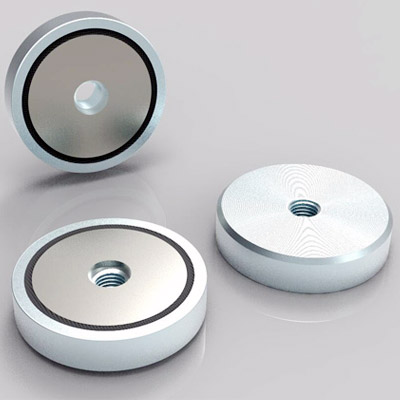

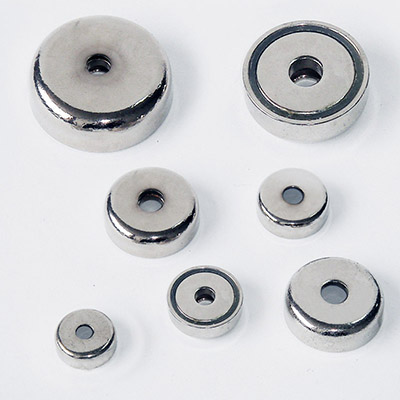

| Hook Pot Magnet(Mounting Magnet) | Countersunk Pot Magnet(Mounting Magnet) |

|  |

| Countersunk Pot Magnet(Mounting Magnet) | Ring Pot Magnet(Mounting Magnet) |

|  |

| Screw Pot Magnet(Mounting Magnet) | Screw Pot Magnet(Mounting Magnet) |

Ring Pot Magnet(Mounting Magnet) Hook Pot Magnet(Mounting Magnet)

Hard Ferrite Pot Magnet(Mounting Magnet) AlNiCo Pot Magnet(Mounting Magnet)

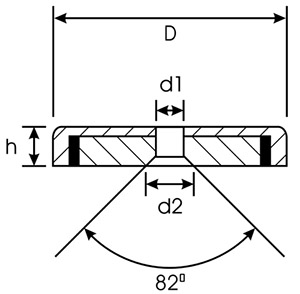

| Item-No. | D(mm) | h(mm) | d1(mm) | d2(mm) | Capacity(kg) |

|---|---|---|---|---|---|

| PC-16 | 16 | 6.5 | 5 | 9.2 | 5.5 |

| PC-19 | 19 | 6.5 | 5 | 9.2 | 9 |

| PC-25 | 25 | 8 | 6.4 | 12.2 | 22 |

| PC-32 | 32 | 8 | 6.4 | 12.2 | 34 |

| PC-38 | 38 | 9.5 | 6.4 | 12.2 | 41 |

| PC-44 | 44 | 9.5 | 6.4 | 12.2 | 68 |

| PC-51 | 51 | 13 | 8 | 15.2 | 81 |

| PC-64 | 64 | 16 | 8 | 15.2 | 113 |

| PC-76 | 76 | 19 | 8 | 15.2 | 164 |

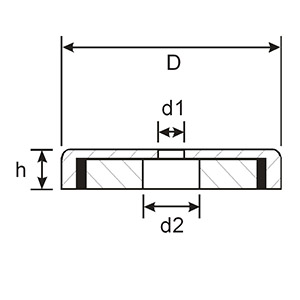

| Item-No. | D(mm) | h(mm) | d1(mm) | d2(mm) | Capacity(kg) |

|---|---|---|---|---|---|

| PR-16 | 16 | 6.5 | 5 | 9.2 | 5.5 |

| PR-19 | 19 | 6.5 | 5 | 9.2 | 9 |

| PR-25 | 25 | 8 | 6.4 | 12.2 | 22 |

| PR-32 | 32 | 8 | 6.4 | 12.2 | 34 |

| PR-38 | 38 | 9.5 | 6.4 | 12.2 | 41 |

| PR-44 | 44 | 9.5 | 6.4 | 12.2 | 68 |

| PR-51 | 51 | 13 | 8 | 15.2 | 81 |

| PR-64 | 64 | 16 | 8 | 15.2 | 113 |

| PR-76 | 76 | 19 | 8 | 15.2 | 164 |

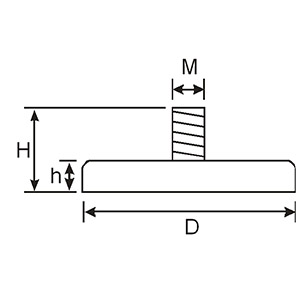

| Item-No. | D(mm) | h(mm) | H(mm) | M-threads (mm) | Capacity(kg) |

|---|---|---|---|---|---|

| PS-9.5 | 9.5 | 5 | 13 | 4.8 | 0.8 |

| PS-13 | 13 | 5 | 13 | 4.8 | 2.5 |

| PS-16 | 16 | 6.5 | 14 | 4.8 | 5.5 |

| PS-19 | 19 | 6.5 | 14 | 4.8 | 9 |

| PS-25 | 25 | 8 | 17.5 | 6.35 | 22 |

| PS-32 | 32 | 8 | 19 | 6.35 | 34 |

| PS-38 | 38 | 9.5 | 20.5 | 6.35 | 41 |

| PS-44 | 44 | 9.5 | 22 | 6.35 | 68 |

| PS-51 | 51 | 13 | 28.5 | 7.94 | 81 |

| PS-64 | 64 | 16 | 32 | 7.94 | 113 |

| PS-76 | 76 | 19 | 38 | 7.94 | 164 |

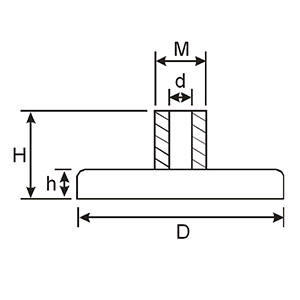

| Item-No. | D(mm) | h(mm) | H(mm) | d-threads(mm) | M(mm) | Capacity(kg) |

| PE-9.5 | 9.5 | 5 | 13 | 4.8 | 8 | 0.8 |

| PE-13 | 13 | 5 | 13 | 4.8 | 8 | 2.5 |

| PE-16 | 16 | 6.5 | 14 | 4.8 | 8 | 5.5 |

| PE-19 | 19 | 6.5 | 14 | 4.8 | 8 | 9 |

| PE-25 | 25 | 8 | 17.5 | 6.35 | 10.5 | 22 |

| PE-32 | 32 | 8 | 19 | 6.35 | 10.5 | 34 |

| PE-38 | 38 | 9.5 | 20.5 | 6.35 | 10.5 | 41 |

| PE-44 | 44 | 9.5 | 22 | 6.35 | 10.5 | 68 |

| PE-51 | 51 | 13 | 28.5 | 7.94 | 13 | 81 |

| PE-64 | 64 | 16 | 32 | 7.94 | 13 | 113 |

| PE-76 | 76 | 19 | 38 | 7.94 | 13 | 164 |

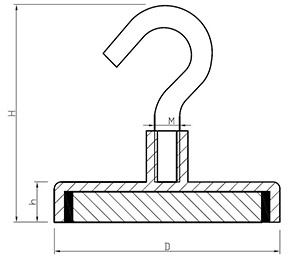

| Item-No. | D | h | H-overall height | M-threads for hook | Capacity(kg) |

|---|---|---|---|---|---|

| PE-16 | 16 | 6.5 | 35 | 4.8 | 5.5 |

| PE-19 | 19 | 6.5 | 35 | 4.8 | 9 |

| PE-25 | 25 | 8 | 48 | 6.35 | 22 |

| PE-32 | 32 | 8 | 48 | 6.35 | 34 |

| PE-38 | 38 | 9.5 | 51 | 6.35 | 41 |

| PE-44 | 44 | 9.5 | 51 | 6.35 | 68 |

| PE-51 | 51 | 13 | 64 | 7.94 | 81 |

| PE-64 | 64 | 16 | 67 | 7.94 | 113 |

| PE-76 | 76 | 19 | 70 | 7.94 | 164 |

We can design and manufacture A Wide Range of Pot Magnets according to clients requirements.

Pot magnets (Mounting Magnets) are made up of magnets (NdFeB, SmCo, AlNiCo or Hard Ferrite) and other spare parts, such as metal, plastic, rubber and other components. Sometimes Pot magnets can meet some special requirements while a single magnet can not do. In the meantime, using pot magnets can save more cost than just using magnets and gain the same purpose.

Pot Magnets (Mounting Magnets) are often used as tools for various activities in workshops and in industry. They can be used for holding workpieces whilst welding, cutting, milling or drilling etc. Because of the lack of moving parts and the robust construction of pot magnets, the life is unlimited and no maintenance is required. Just keeping the pole surface clean guarantee reliable operation and a long life.

How to choose a pot magnet?

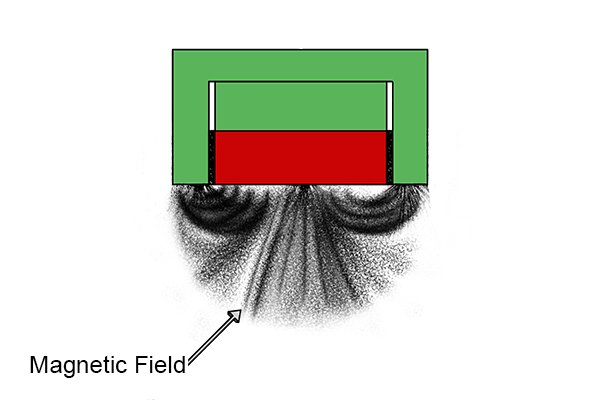

The basic principle of the holding or pot magnet is to direct and concentrate the flux from both magnetic poles to one active face. This is usually achieved with steel pole pieces or a steel-backing cup.

The standard selection can be broken down into three material types and there is a great variety of systems available. The following data should act as a simple guide:

1) Rare Earth Samarium & Neodymium, pots and assemblies can offer up to eleven times the performance of a Ferrite system in a comparable size. Applications tend to be specialized engineering projects where performance and available space are key factors. Maximum operating temperatures are +60°C for the Neodymium and +150°C - +250°C for the Samarium depending on the design configuration.

2) Sintered Ferrite, this material offers a good performance from an inexpensive magnet, however, they tend to be bulky and are not always suitable where space is an important factor. The steel parts are plated & the Ferrite is inert thus corrosion is limited. Maximum operating temperature is +120 °C.

3) Cast AlNiCo, offers a better holding force than Ferrite systems and is the only pot magnet that can be heated to extreme temperatures. However, the high cost of the Cobalt content in the cast magnet makes the price prohibitive unless the application requires temperatures over +120°C up to a maximum of +500°C.When considering your selection, please be aware of the following factors: The stated Kg Pull (holding/gripping force) is based on the magnets retaining force against a direct pull when offered to a clean ground mild steel surface with a minimum thickness of 8mm. Painted or un-ground surfaces will reduce this force, assemblies working in shear will support approximately 1/3 of the stated value.

Pot Magnets

What is a Pot Magnet?

A Pot Magnet is a special type of permanent magnet that is embedded with a powerful NdFeB magnet and are encased in a steel shell which increases its magnetic power by a huge amount. This steel shell in which the magnet is enclosed is often referred to as a pot and therefore the name is given to it as a pot magnet. This pot magnet is also known as a Cup magnet or a Mounting magnet as it can be mounted over any metallic surface. The pot magnet comes in various shapes and sizes according to the user needs as the mounting magnet comes with a small hole in which nuts and bolts can be attached.

Since the pot magnet contains a permanent magnet inside it there is no need for an electric supply to attain its magnetic properties and, thus it readily emits an infinite amount of magnetic field. The steel shelf that encloses the pot magnet helps in increasing its holding power and provide the magnet with additional strength and stability. A pot magnet has a wide range of uses like it is mostly used as a magnetic base or magnetic holder in several places ranging from supermarkets to our own homes.

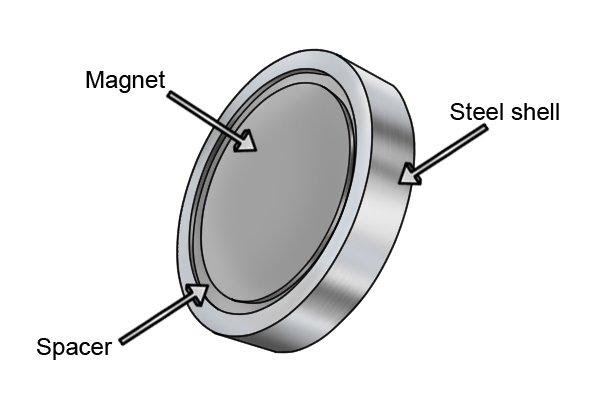

Components of a Pot Magnet

Now let's discuss the important parts which constitutes a pot magnet.

Magnet

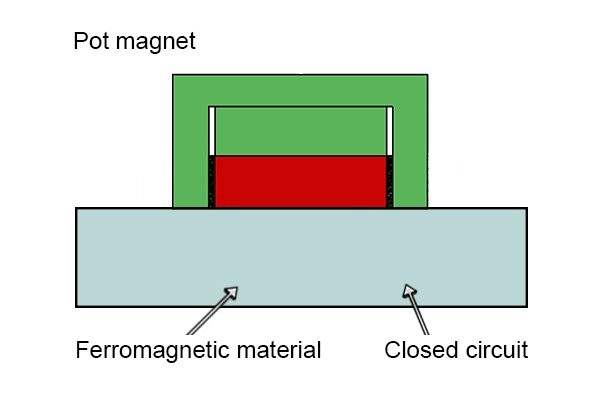

The Steel shell that has enclosed the magnet is placed in such a way that only one face of the magnet is exposed to the environment while the other one is covered, thus allowing the magnetic properties to act at only one face of the steel pot. The circular neodymium magnet has its north pole in the centre and its south pole around the edges. This determines the magnetic lines of force of the pot magnet as well where this kind of configuration of the two magnetic poles results in the formation of a closed-circuit, whenever any type of ferromagnetic material comes in contact with it.

In such kind of a closed-circuit, the magnetic field is trapped within the material and the magnet as soon as it gets attached to it. This gives the magnet a much stronger hold on the ferromagnetic material. Now since the magnetic lines of force run parallel to the magnet, therefore, despite getting a strong magnetic hold on any material, the magnetic effect is only limited to a very small range which means the ferromagnetic material must be very close to the magnet to get attracted towards it.

Steel Shell

The steel shell acts as a protective casing for the magnetite and prevents it from breaking or cracking down from contact with a solid surface. It provides additional durability and strength to the magnet, without which it would have been fragile and even allows threaded openings and studdings to be inserted. The steel shell helps the magnet increase its magnetic power by 32 times by concentrating all its magnetic lines of force into one side of the steel pot. Due to its steel shell, the magnet can be entered into metallic materials, but still, it wouldn’t lose its magnetic power and wouldn’t be demagnetised.

Pot Magnet Spacer

Now inside the pot magnet, there is a tin space of air that separates the magnet from the steel shell. This is done so that the steel shell may not have any kind of demagnetising effect on the permanent magnet. This spacer can be made up of either brass or plastic, as suitable by the manufacturer.

Rubber Cap or Rubber Coating

A pot magnet generally has a rubber coating on top of its steel shell, this prevents the magnet from getting scratch on uneven surfaces, such as car roof, etc. If there is no rubber coating people can even buy rubber caps that does the same job. These rubber coatings and caps provide the magnet with proper friction which in turn helps them to be clamped on vertical surfaces and reduced the risk to slide off easily.

Working of a Pot Magnet

A pot magnet functions by attaching itself to any kind of ferromagnetic materials present near it. The steel shell attached to the pot magnet ensures that it greater magnetic strength which allows it to hold more metallic materials with greater strength. The reason behind it is that, unlike horseshoe or bar magnet where the magnetic lines of force are spread all over outside the magnet and not concentrated on the exterior cover attached to it, reduces its magnetic power, whereas in a pot magnet all the magnetic lines of forces are gathered in one area and does not go beyond the sides of the exterior cover, this gives increased magnetic strength to the pot magnet. The pull energy of the magnet holds all the metallic substances in one place with a constant magnetic force. This pull force of a particular magnet depends upon factors such as the coating or any damage it has suffered. With a high pull force, a pot magnet can attract and hold on to more metallic material.

Features of Pot Magnets

Since Pot magnets have only one surface of magnetic attraction, it prevents the spread of their magnetic field, this, in turn, prevents all the other ferromagnetic materials near it from getting magnetised. As pot magnets are made up of permanent neodymium magnets they can indefinitely retain their magnetic force.

Application of Pot Magnets

These magnets are very versatile and are designed in such a way that they can be used in almost all of the essential places. Pot magnets can be used in various places ranging from magnetic light fittings and exhibition display signs to doorsteps and tow lights. They are even popular for industrial use such as in the metal and steel industry, and even in tool shops.

Precautions

While using pot magnets some precautions should be taken. The pot magnets must not be exposed to prolonged radioactive radiations as it will severely affect the magnetic strength of the magnet. These magnets should be used under permissible temperatures as high temperature might lead them to lose their magnetic strength. People should also check the lifting capacity of the magnets before buying them.

Conclusion

So these were the important things that one needed to know before buying and using a pot magnet. It’s small, simple, easy to use and has a tremendous high magnetic strength when compared to its size.